Summary:

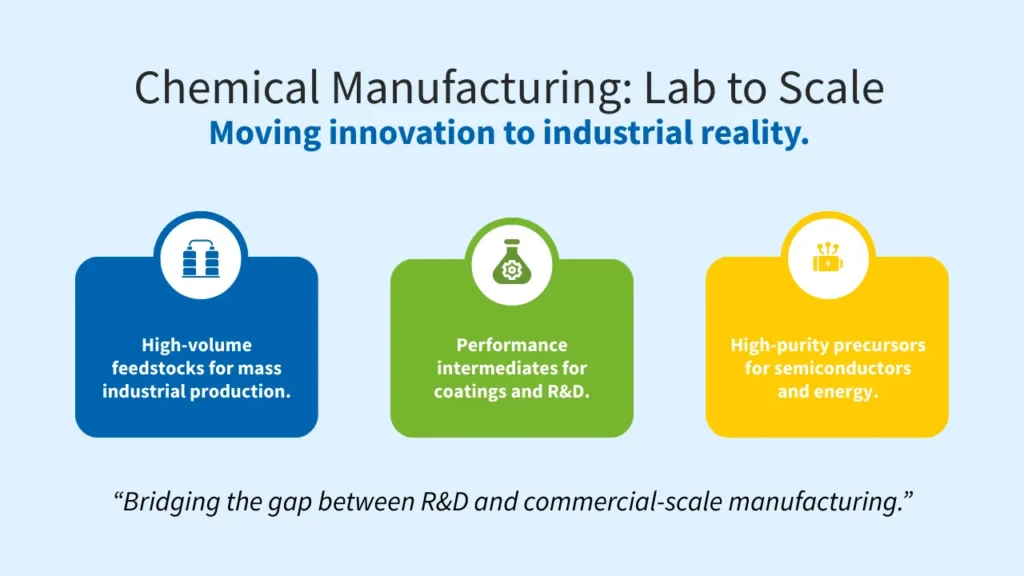

Chemical manufacturing is the industrial-scale conversion of raw materials into chemical intermediates and compounds using engineered reactions, separation, purification, and scale-up technologies. It enables reliable, cost-competitive, and safe chemical production that supports innovation across multiple industries.

In this in-depth guide, you will learn what chemical manufacturing truly involves, how the chemical manufacturing process works end to end, the major types of chemical manufacturing industries, real-world product examples and use cases, and how technology, IP protection, safety, and cost efficiency shape modern chemical manufacturing, especially at the R&D, pilot, and intermediate production stages.

What Is Chemical Manufacturing?

Chemical manufacturing is the structured and repeatable transformation of raw materials—such as hydrocarbons, inorganic minerals, bio-based feedstocks, air, and water, into value-added chemical products and intermediates through controlled chemical and physical processes.

Unlike laboratory chemistry, which focuses on discovery and proof of concept, chemical manufacturing focuses on industrial scale manufacturing.

This means ensuring that a reaction can be reproduced consistently, safely, economically and sustainably at scale inside a chemical manufacturing plant.

The chemical manufacturing industry acts as the bridge between scientific innovation and real-world industrial application. It converts molecular ideas into tangible chemical supply that downstream industries depend on.

Why Chemical Manufacturing Is Fundamentally Different from Lab Chemistry

- Lab chemistry prioritizes feasibility; chemical manufacturing prioritizes repeatability

- Lab reactions tolerate variability; industrial chemical production cannot

- Scale introduces safety, heat transfer, mass transfer, and impurity challenges not visible at lab scale

Example: A reaction producing 95% yield in a lab flask may fail give same results at industrial scale due to uncontrolled heat release. Chemical manufacturers redesign reactor configuration, mixing, and process parameters to make the chemistry scalable and safe.

How the Chemical Manufacturing Process Works (Step-by-Step)

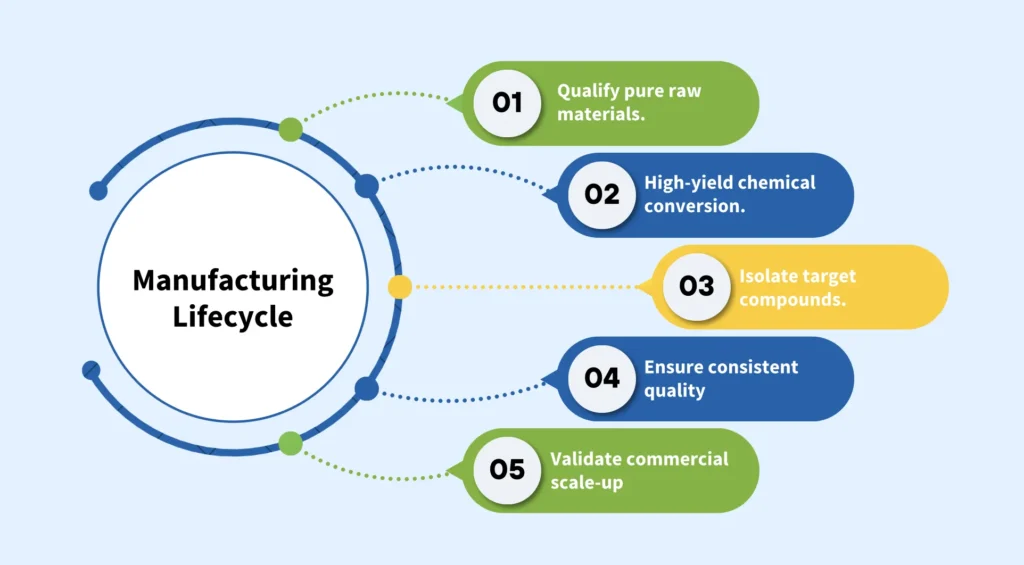

The chemical manufacturing process follows a structured lifecycle designed to reduce technical, safety, and commercial risks.

1. Raw Material Selection and Feedstock Preparation

Raw materials are evaluated based on purity, availability, long-term supply security, safety profile, and cost structure. Feedstocks may require drying, filtration, size reduction, or blending before use.

Use case: In electronic chemicals, even trace metal impurities in solvents can affect device performance. Chemical manufacturers therefore implement strict feedstock qualification protocols.

2. Reaction Engineering and Chemical Conversion

This is the core of chemical manufacturing. Chemical reactions may involve:

- Catalysis

- Polymerization

- Oxidation or reduction

- Esterification or alkylation

- Gas-phase or high-pressure transformations

Modern chemical manufacturing plants increasingly rely on advanced reactor design, including continuous-flow systems, to improve safety and reaction control.

Example: Flow chemistry is often used for hazardous or highly exothermic reactions in agrochemical intermediate synthesis, significantly reducing risk compared to traditional batch processing. Fow chemistry offers multitude of surface to volume ratios, a batch process may have surface area/reaction volume ratio of ~ 1, whereas the same process if conducted in flow reactors surface area/reaction volume ratios can be achieved between 200 to 300 times, giving huge advantage of heat transfer, mixing and mass transfer advantage.

3. Separation, Isolation, and Purification

Post-reaction mixtures contain unreacted materials, by-products, solvents, and catalysts. Separation technologies such as distillation, crystallization, extraction, filtration, and membrane processes are applied to isolate the target compound.

Industrial use case: Multi-stage crystallization is used to achieve high-purity specialty chemical products required for performance-sensitive applications like polymers and electronics.

4. Quality Control and In-Process Monitoring

Quality in chemical manufacturing is embedded into the process rather than inspected at the end. In-process controls, analytical testing, and batch monitoring ensure consistent chemical composition and performance.

Example: Real-time monitoring of reaction completion prevents over-processing, reduces degradation, and improves overall chemical production efficiency.

5. Scale-Up and Process Optimization

Scaling a reaction from lab to pilot to commercial scale introduces challenges such as heat removal, mass transfer limitations, and safety risks. Pilot-scale manufacturing validates process robustness before full-scale deployment.

Use case: Pilot trials are used to confirm reactor sizing, agitation requirements, and impurity profiles before commercial chemical production begins.

Products from the Chemical Industry (With Examples)

The chemical industry produces materials that enable nearly all modern manufacturing sectors.

Industrial Chemicals

Industrial chemicals are high-volume materials used as building blocks.

Examples and applications:

- Acids and alkalis for metal processing and water treatment

- Solvents for textiles, inks, and industrial cleaning

Specialty Chemical Products

Specialty chemical products are performance-driven and application-specific rather than volume-driven.

Examples:

- Resin intermediates that improve coating durability

- Polymer additives that enhance heat or UV resistance

- Electronic chemical intermediates for semiconductor manufacturing

These products demand precise chemistry and tight impurity control, making specialty chemical manufacturing highly technical.

Advanced Intermediates and Materials

Chemical production companies increasingly focus on advanced intermediates that support emerging technologies.

Use cases:

- Battery material intermediates for energy storage systems

- Polymer precursors for lightweight automotive and aerospace components

- Electronic-grade intermediates for PCB and semiconductor fabrication

- Ingredients for flavours and fragrances, food additives

- Stabilizers and additives for fast moving consumer goods

Types of Chemical Manufacturing Industries Explained

The chemical manufacturing industry is segmented based on scale, complexity, and end use.

Basic Chemical Manufacturing

Focuses on large-volume, standardized chemicals such as ammonia, chlorine, methanol, and ethylene.

Use case: Ethylene serves as a feedstock for plastics, solvents, and synthetic fibers.

Specialty Chemical Manufacturing

Specialty chemical manufacturing produces lower-volume, high-value chemicals tailored to specific applications.

Example: Custom intermediates designed for high-performance coatings or specialty polymers.

Fine and Performance Chemicals

Fine chemicals are high-purity intermediates used in pharmaceuticals, electronics, and agrochemicals.

Use case: Consistent intermediates enabling reliable downstream synthesis without variability.

Petrochemicals and Polymers

Transforms hydrocarbons into plastics, elastomers, fibers, and polymer building blocks.

Example: Polymer precursors used in engineering plastics and composite materials.

Sustainable and Green Chemical Manufacturing

Focuses on bio-based feedstocks, energy-efficient processes, and reduced environmental impact.

Use case: Replacing fossil-derived intermediates with bio-based alternatives in material science.

Cost Competitiveness in Modern Chemical Manufacturing

Cost competitiveness in chemical manufacturing is achieved through engineering efficiency, not cost-cutting shortcuts.

Key Drivers of Cost-Competitive Chemical Production

- High-selectivity reaction routes to minimize waste

- Flow and continuous processing to improve yield and safety

- Reduced solvent and energy consumption

- Shorter batch cycle times

- Integrated quality systems that prevent rework

Example: Optimizing a multi-step synthesis route to reduce one purification step can significantly lower operating costs while improving throughput.

Intellectual Property (IP) Protection in Chemical Manufacturing

In chemical manufacturing, IP often resides in process know-how rather than molecular structure alone.

IP-Sensitive Elements Include:

- Reaction routes and catalysts

- Operating conditions and control strategies

- Purification and isolation techniques

Use case: Pilot-scale manufacturing of proprietary intermediates under controlled access ensures IP protection while validating scalability.

Protecting IP is especially critical in specialty chemical manufacturing and advanced materials development.

Chemical Manufacturing Industries and Their Applications

| Chemical Manufacturing Segment | Typical Outputs | Industry Applications |

| Basic Chemicals | Acids, alkalis, solvents | Construction, textiles, water treatment |

| Specialty Chemicals | Performance intermediates | Electronics, automotive, energy |

| Agrochemical Intermediates | High-purity intermediates | Crop protection synthesis |

| Advanced Materials | Polymer precursors | Batteries, composites, semiconductors |

Why Choose Novopor as Chemical Manufacturing Partner?

Within the chemical manufacturing ecosystem, intermediaries that operate between laboratory research and full-scale production play a critical role. They enable innovators and enterprises to move from concept to commercialization with reduced risk.

From an industry perspective, this model supports:

- Faster lab-to-market transitions

- Lower scale-up and safety risks

- Predictable manufacturing economics

- Reliable, repeatable chemical supply

- Continuous improvement of quality, yield and energy

Conclusion: Why Chemical Manufacturing Matters

Chemical manufacturing transforms chemical science into industrial reality. From industrial chemicals to advanced specialty intermediates, the chemical manufacturing industry underpins progress across energy, electronics, agriculture, and materials science.

As demand grows for safe, scalable, and cost-competitive chemical production, the importance of advanced chemical manufacturers, especially those supporting R&D and pilot-scale development will continue to increase.

Frequently Asked Questions

They include basic chemicals, specialty chemicals, fine chemicals, petrochemicals,

agrochemicals, advanced materials, and sustainable chemical manufacturing

segments.

Basic chemical manufacturing produces large-volume, standardized chemicals used

as feedstocks for downstream chemical and industrial processes

Chemical manufacturing converts raw materials into chemical intermediates and

compounds economically, through controlled reactions, purification, and industrial

scale-up

Examples include polymer precursor synthesis, specialty coating intermediates,

electronic chemical production, industrial solvents, agrochemical intermediates and

active pharmaceutical intermediates.