In the agrochemical industry, the reliability and quality of chemical intermediates directly determine the success of every formulation produced, whether herbicides, insecticides, or fungicides.

While final formulations get the spotlight, their performance, stability, and regulatory success depend heavily on one foundational element, the quality and consistency of the intermediates used to produce them.

This is why choosing the right manufacturing partner for the agrochemical industry is a key procurement activity. It is a strategic decision important for ensuring successful product outcomes, strengthening operational reliability, and driving long-term competitiveness.

Partners like Novopor offer proven competence in high-purity intermediates, strong R&D capability, and sustainable manufacturing practices, which can significantly strengthen a manufacturer’s production ecosystem and long-term growth trajectory.

Why Choosing the Right Intermediate Chemical Supplier Matters

For agrochemical companies, intermediates and technical (Active ingredients ) are the backbone of active formulation.

These specialty agrochemical intermediates undergo multiple complex reactions and transformations before reaching the final product stage.

Small deviation in intermediate and technical purity or consistency can trigger following issues for agrochemical companies:

Manufacturing Failures

Unexpected side reactions or low yields during synthesis often originate from inconsistent intermediate quality.

Regulatory Issues

Global agencies now enforce strict purity limits, residue restrictions, and environmental impact standards. Poor-quality intermediates can result in delayed approvals or failed audits.

Inconsistent Field Performance

A product that underperforms due to variable intermediate purity can damage brand reputation and reduce market confidence.

In short, the agrochemical supply chain is high-stakes. Stability, process efficiency, and product performance all depend on the reliability of agrochemical intermediates CDMO partners like Novopor.

Benefits of Reliable Strategic Outsourcing Partner

A dedicated manufacturing partner provides critical capabilities that go beyond simple sourcing:

- R&D and Innovation Support: Strong collaboration accelerates product development and improves yields. This includes expertise in new chemistries trend, such as flow technology, continuous flow, and biological.

- Geographical Diversity and Cost Competitiveness: Partners with geographical diversity in their manufacturing footprint can better manage supply chain risks and enhance cost competitiveness.

- Market Concentration: Expertise in the concentration of intermediates allows for process efficiency and better material management.

- CDMO Outsourcing by Innovation: Partnering allows companies to leverage specialized expertise and innovation through Custom Development and Manufacturing Organization (CDMO) outsourcing, optimizing complex synthesis steps.

Evaluating Quality and Process Control in a Supplier

Raw Material Quality

The foundation of any agrochemical lies in its intermediate quality. Reliable suppliers must demonstrate excellence in advance quality and consistently across all batches.

A trustworthy supplier should offer:

- Batch-to-Batch Purity Consistency

Consistent purity ensures smooth chemical reactions. Partners must provide detailed Certificates of Analysis (CoA) verifying specifications for every shipment.

- Advanced Traceability

A world-class quality measures protocol should track each input and output throughout production. This protects agrochemical companies from risk, regulatory scrutiny, and costly recalls.

- Controlled Manufacturing Environment

Stable reactions depend on controlled temperatures, equipment calibration, and robust SOPs. Suppliers lacking these systems can become liabilities.

In the agrochemical manufacturing cycle, poor intermediate or technical quality often translates into higher downstream processing costs, wasted time, and failed quality checks. This makes it essential to prioritize or CDMO Partners with proven quality credentials.

Stable reactions depend on selection of optimal equipment and design controlled temperatures, precise operating conditions, equipment calibration, and robust SOPs. These factors should consider for selecting the right agrochemical partner or outsourcing CDMO partners.

Supply Chain Reliability and Scalable Production Capacity

The agrochemical market is highly seasonal. When demand peaks, manufacturers must scale production quickly without sacrificing quality.

This requires suppliers or CDMO Patner capable of moving from Lab scale to pilot-scale production to multi-ton commercial manufacturing seamlessly.

Key Factors That Indicate Supply Chain Reliability

- Infrastructure Readiness

A strong partner has multiple manufacturing units, diversified locations, advanced reactor systems, and the capability to handle sensitive advance chemistry such as hydrogenation, chlorination, or nitration.

- Inventory and Logistics Strength

Suppliers must ensure steady availability through proactive inventory planning, diversified logistics networks, and on-time delivery. In a sector where timing affects market share, delays are costly.

A scalable and dependable supplier ensures uninterrupted production, helping agrochemical companies meet their market commitments without delays.

The Critical Role of Technical Expertise and R&D Collaboration

The best global custom manufacturing partners go beyond supplying intermediates—they work side-by-side with your technical, R&D, and production teams of agrochemical companies to solve challenges and accelerate innovation.

How Strong R&D Support Adds Value

- Process Optimization and Continuous Improvement

An experienced R&D team can redesign reaction pathways, continuous improvement and improve yields, reduce manufacturing costs, waste management and shorten overall production and batch cycle time.

- Custom Synthesis Capability

When companies develop new AIs or intermediates, a supplier with custom synthesis experience becomes invaluable. They can scale new molecules from grams to commercial tonnage efficiently.

- Faster Time-to-Market

Suppliers with technical expertise help agrochemical manufacturers avoid expensive trial-and-error methods, enabling faster commercialization of new products.

Compliance, Certifications, and Global Regulatory Readiness

Agrochemical manufacturers thrive when partnered with suppliers who uphold rigorous global standards such as EPA, REACH, and FAO. Working with a supplier equipped with strong compliance systems ensures smoother approvals, faster market entry, and long-term regulatory confidence.

Essential Certifications to Look For

- EcoVadis (for Sustainability Performance)

- Responsible Care (RC)

- TFS (Together for Sustainability)

- ISO 9001 – Ensures quality management

- ISO 14001 – Ensures environmental management

- Good Laboratory Practices (GLP) – Supports reliable research documentation

- REACH Compliance – Required for global chemical exports

Suppliers must demonstrate readiness for extensive regulatory audits, documentation checks, and environmental assessments.

Focus on HSE Practices

Health, Safety, and Environment systems ensure the supplier:

- Handles chemicals responsibly

- Follows strict safety protocols

- Minimizes hazardous emissions

- Properly treats waste

A supplier with strong EHS standards ensures your supply chain remains compliant, environmentally conscious, and globally competitive.

Building a Long-Term Strategic Partnership

Choosing a chemical supplier should not be a short-term transaction—it must be a strategic partnership. The cost of switching suppliers or handling substandard batches far outweighs any short-term price benefits.

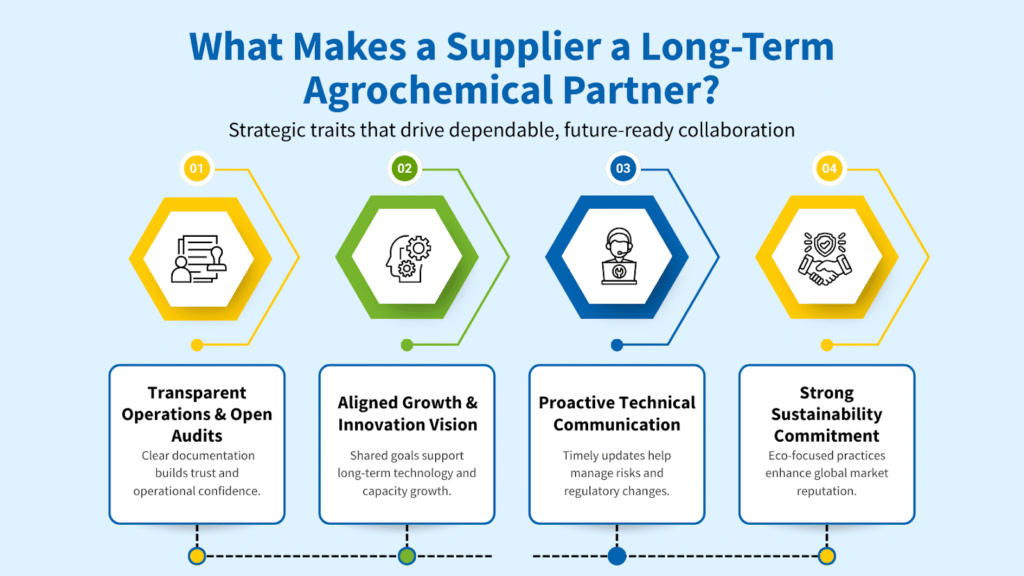

What Makes a Supplier a Long-Term Partner?

- Aligned Growth Vision

Your partner should be committed to innovation, expanding capabilities, and supporting your long-term goals.

- Proactive Communication

From discussing upcoming market changes to alerting about regulatory updates, proactive communication ensures strategic alignment.

- Transparency and Openness to Audits

A strong supplier welcomes regular financial, technical, and process IP audits.

Many agrochemical companies prefer working with partners like Novopor, whose focus on advanced intermediates and custom solutions builds long-term trust and technical rapport.

Sustainability, ESG, and the Modern Supply Chain

Today’s agrochemical companies are increasingly judged on environmental responsibility. This extends not only to the final formulations but also to the intermediate sourcing process.

As the industry evolves, the most valuable partners offer an integration platform with biologicals. This approach supports the development of hybrid solutions where advanced chemical intermediates work synergistically with biological inputs, catering to modern, sustainable farming practices.

Why Sustainability Matters in Supplier Selection

- Green Chemistry Integration

Suppliers using energy-efficient processes, safer solvents, and waste minimization methods help manufacturers align with global ESG expectations.

- Reduced Carbon Footprint

Suppliers committed to renewable energy use, recycling systems, and efficient resource use support a cleaner value chain.

- Improved Brand Reputation

Environmentally responsible sourcing enhances brand trust among stakeholders, regulators, and global buyers.

A sustainability-focused supply chain also safeguards long-term operational resilience.

Choose Wisely, Grow Strategically

Finding the right advanced chemical supplier for the agrochemical industry is about procurement, it is about protecting your product quality, scaling your manufacturing capacity, ensuring regulatory compliance, and building future-ready sustainability practices.

With rising global food needs and increasing regulatory pressure, agrochemical manufacturers need suppliers who bring technical expertise, reliability, and innovation.

A partner like Novopor, with proven competence in high-purity intermediates, strong R&D capability, and sustainable manufacturing practices, can significantly strengthen your production ecosystem and long-term growth trajectory.

Contact us today to explore geographical diversity, cost competitiveness, and reliable chemical sourcing partnerships.

Frequently Asked Questions

Agrochemical companies should prioritize raw material quality, regulatory compliance, scalable capacity, and technical expertise—areas where experienced partners like Novopor add long-term value.

High-purity and consistent intermediates directly impact reaction efficiency, regulatory approvals, and final product performance in agrochemical production.

Sustainable chemical sourcing helps meet ESG goals, reduce regulatory risk, and build a resilient agrochemical supply chain for the future.

Sustainable chemical sourcing helps meet ESG goals, reduce regulatory risk, and build a resilient agrochemical supply chain for the future.

Yes, manufacturers with strong R&D, process control, and supply chain reliability such as Novopor can significantly accelerate development and commercialization timelines.